A Heavy Duty Grease Guide

While the Machine Age was in full swing in the late 1800s and early 1900s, the quality of life improved greatly. Operating larger machines was crucial towards creating this better way of life, whether it was tractors or steam engines, or automobiles. The technology developed all those years ago is still relevant to this day and age, and many of those inventions are still commonplace. When it comes to operating heavy machinery, a professional knows every bit and piece about the machine. Countless hours are spent researching the machine, how it functions, what its purpose is etc. All people who own heavy machinery know the importance of taking care of his or her product. Replace parts when they break, fix parts that clank and clunk, and grease pieces so the machine runs as smoothly as it did on its first day. But as heavy machinery becomes more commonplace, the users are becoming less knowledgeable about taking care of his or her product.

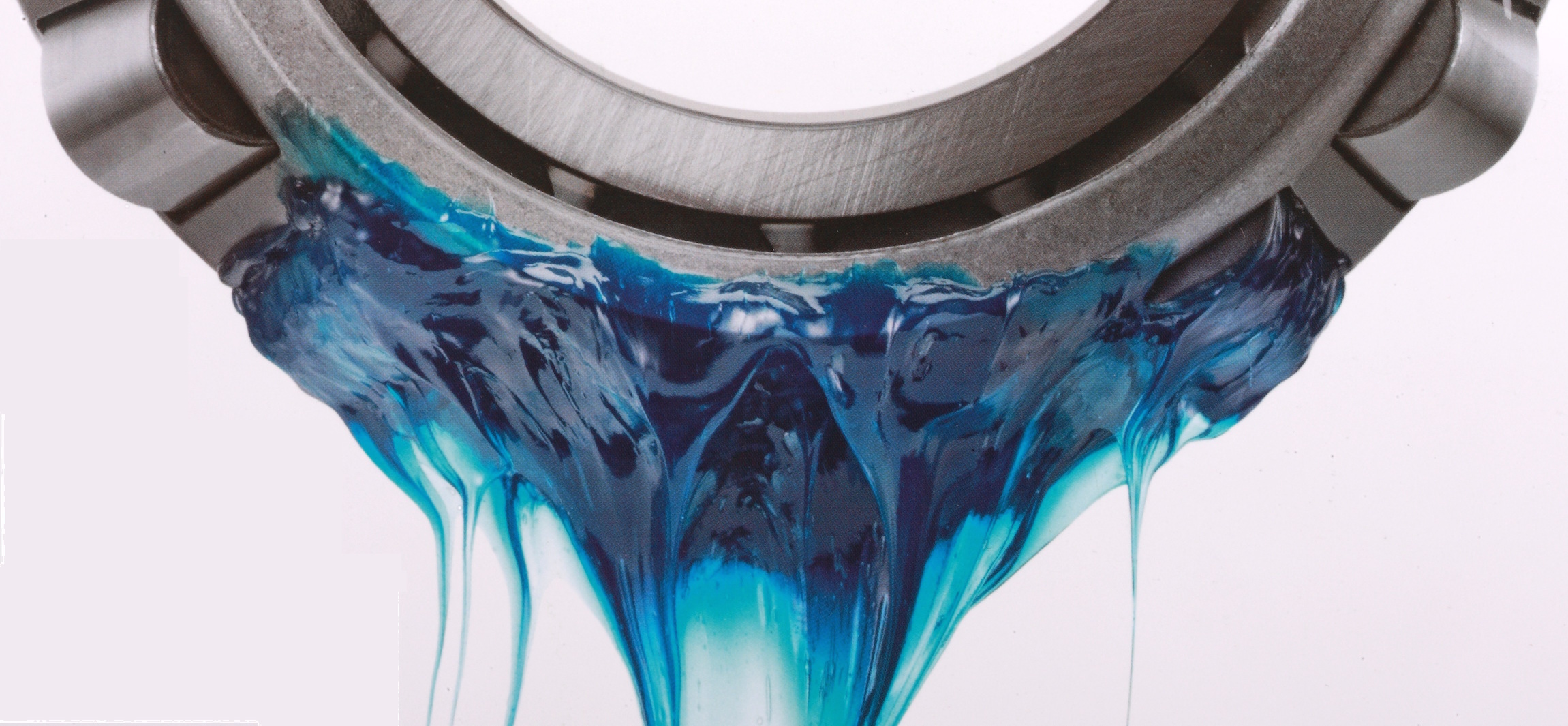

The Basics of Grease

Before a consumer purchases a grease, there is some basic information to have prior to the purchase. The first thing to do is look at the owner’s manual of the heavy machinery. Look for what the relubrication intervals are. Relubrication intervals are how frequently the owner will have to replace the grease that had deteriorated. If the manual has been lost or cannot be viewed, then a rough estimate will have to be made using the type of bearings, hours of use, and average temperature when the heavy machinery is in use. For example, the higher the temperature the more often the machine will need to be lubricated. The owner’s manual will also detail the recommended greases for that particular machine. It is incredibly important that the user does not use just any grease for the relubrication of his or her heavy machinery.

Another key piece of information is the temperatures and environment where the machinery will operate. As mentioned previously, the temperature is important in knowing how frequently the grease will need to be reapplied. Some greases even have a cold-resistance feature. Having a tractor sitting outside versus under a roof will have a higher rate of water contamination and will ultimately require more grease. Even the amount of friction or risk of rust buildup are important factors that play into the type of grease for the job. Dirt and dust are also contamination issues to be mindful of.

Before reaching a store, the consumer should know what NLGI means and the consistency grade scale. At one time NLGI stood for the National Lubricating Grease Institute. But, due to concerns from some non-US companies who objected to the term "National," the board amended the name of the organization to just NLGI with no meaning for the letters. This institute developed the NLGI Consistency Grade Scale, which assigns numerical ratings in relation to the hardness of the grease. The scale ranks as follows: 000 is very fluid, 00 is semi-fluid, 0 is fluid, 1 is soft, 2 is medium, 3 is medium-hard, 4 is hard, 5 is very hard, and 6 is block. The lower numbers (from 000 to 1) are softer and easier to pump over longer distances. Generally, if the consumer has a longer hose or is in cooler temperatures, number 1 greases are best. Number 2 greases are usually recommended by manufacturers due to their ability to stay in place over wider and more normal temperature ranges. They are also the most common hardness for grease and its consistency.

NLGI-certified is a common phrase when talking about greases. Some greases have a NLGI certification mark. For example, a designation of LB means that the grease is suitable for use as a chassis lubricant and a GC-LB designation means that the grease is suitable for use in wheel bearings or as a chassis lubricant.

Types of Greases

There are a variety of greases on the market. Overall, there are three main types of grease: GP, MP and EP. General purpose (GP) grease implies that the grease could be used anywhere but this is not the case. GP grease is an all-purpose grease which is ideal for squeaky fences to rattling cars. GP greases are also typically lower in cost and used where premium performance is not a requirement. GP grease is mostly used on lightly loaded bearings that require frequent lubrication.

MP grease is a multi-purpose grease. MP greases rank as an NLGI number 2 and can handle the job of lubricating more important parts than a simple swivel hitch and may not require as frequent relubrication.

EP grease is a grease designed for extreme pressure. Putting AP or MP grease in situations where the grease will be put under such high pressures may cause more wear to the machinery in the long run. However, EP grease can be used almost anywhere that AP or MP grease would be needed. EP grease typically has molybdenum and/or graphite, which provides an extra layer of protection in the grease and reduces the amount of friction between various parts significantly.

A Closer Look at Each Grease

For every type of grease (GP, MP, EP), there are whole varieties of brands of greases within. For example, within the EP grease category, there is a subsection for Moly EP grease. This type of grease is designed for extreme pressures like all the other EP greases in its category. However, Moly EP grease contains molybdenum disulfide. Typically, greases with molybdenum disulfide in them are better suited for places with lots of dirt and dust. Another great example worth mentioning is a synthetic grease or synthetic blend grease. Greases with synthetic blends are more oxidation resistant and can be used on cars and trucks alike. Some benefits of synthetic blends are the added protection in colder temperatures. A full synthetic grease has all of these features plus high-temperature oxidation resistance.

Things to Consider

When going to purchase a grease, consider all the factors already discussed: the recommended grease, the various types of greases, the weather and environment, the NLGI ratings, etc. The more of these factors impact the chosen grease, the more satisfied with the performance the consumer will be. It’s important to explore each type of grease and find one that is best suited for the consumer’s application needs. Where a Moly EP grease is useful, a general purpose grease may not. Really look at the packaging of the greases to determine if that specific grease will work with the intended purpose in mind.

The most important thing to do when purchasing grease is to be informed. Trying to talk to a salesperson can be intimidating and there’s always the lingering thought in the back of all consumers’ heads that they might be paying a ridiculous amount of money for a grease that might not even work. Another thing to avoid is settling for a grease that seems to be equally effective but for a lower cost. While saving money and avoiding over-paying for a product is important, grease is a product that is worth the extra cash. If a product is not properly greased, it can ruin the longevity of the machinery permanently. It is far better to have a grease that will last longer and run more effectively than have a grease that will not properly lubricate and be rendered useless. Grease, quite literally, keeps things running. Without grease, the great machines of the late 1800s and early 1900s would cease to operate. Cars would no longer drive and tractors would no longer operate. In many ways, grease has changed. NLGI has created ways for the common consumer to learn about grease and begin to identify the types of grease, what each grease is used for, and how vicious each grease is. An average consumer looking to grease his or her product can now easily find what to look out for in a grease and what to avoid. While most people might remain unknowledgeable on all the specifics on his or her heavy machines, there is no longer a reason to remain uneducated on this very important aspect of maintaining a piece of heavy machinery.