According to the National Lubricating Grease Institute, 70 percent of the grease sold worldwide is based on either simple lithium soaps or lithium complex thickeners. This article will describe what each grease is, what its functions are, and how to choose which grease best fits your needs.

History

In March of 1942, an American chemical engineer named Clarence E. Earle was granted a patent for an invention called "Lubricant Containing Lithium Salts". This was the first grease based on simple lithium soaps, ushering in a new era in the lubricating grease industry.

Before Earle's invention, the most common lubricant was an alkali metal soap. His lithium soap process provided vast improvements over its alkali counterpart, including better water resistance, better high-temperature properties, and excellent mechanical properties, including better pumpability and resistance to shearing. Although it typically costs more to manufacture than other grease types, its improved performance offsets the extra cost.

In March of 1947, Lester W. McClennan was granted a patent for the first lithium complex grease, but it did not catch on as quickly as Earle's invention. It wasn't until the 1980s that lithium complex greases began to gain market popularity and displace simple lithium greases as the industry favorite.

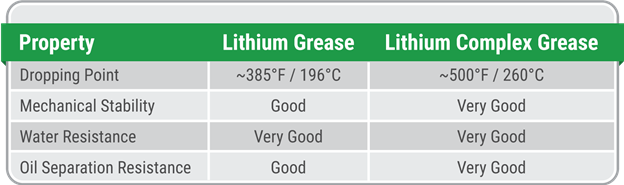

Dropping Point

Lithium complex greases differed by having a higher dropping point, which allows the grease to work at higher temperatures. This is due to a second thickener component, known as the complexing agent. For example, modern lithium complex greases typically use a shorter chain-length difunctional carboxylic acid such as azelaic or adipic acid.

Shear Stability

Mechanical stability, also known as shear stability, is the ability of a grease to maintain its consistency when subjected to mechanical shear forces. Both simple lithium and lithium complex greases are resistant to breakdowns typically caused by shear force. This makes them popular options for a wide range of applications.

Water-Resistance

The overall water-resistance of simple lithium and complex lithium greases is related to the solubility of the thickener. Lithium hydroxide and the thickeners based on it have limited solubility. This means that both greases are resistant to absorbing water and being washed away. These water-resistant properties can also be enhanced by adding polymer additives in small concentrations.

Although other thickener types with better water-resistant properties exist, these products have negative properties that make them less desirable for many applications.

Oil Separation Resistance

Oil separation resistance relates to the product's lubrication ability and storage stability. The grease must release enough oil during application in different contact zones, such as bearings and gears, while only releasing a limited amount of oil while in storage. If too much oil is released, the product performance declines.

Table 1. Properties of Lithium and Lithium Complex Greases

Simple lithium and lithium complex greases are popular for various applications due to their overall versatility and excellent properties. Deciding which one is best for your needs comes down to temperature requirements and budgets. Both have exceptional abilities in a wide variety of uses and will be helpful in a variety of site applications.